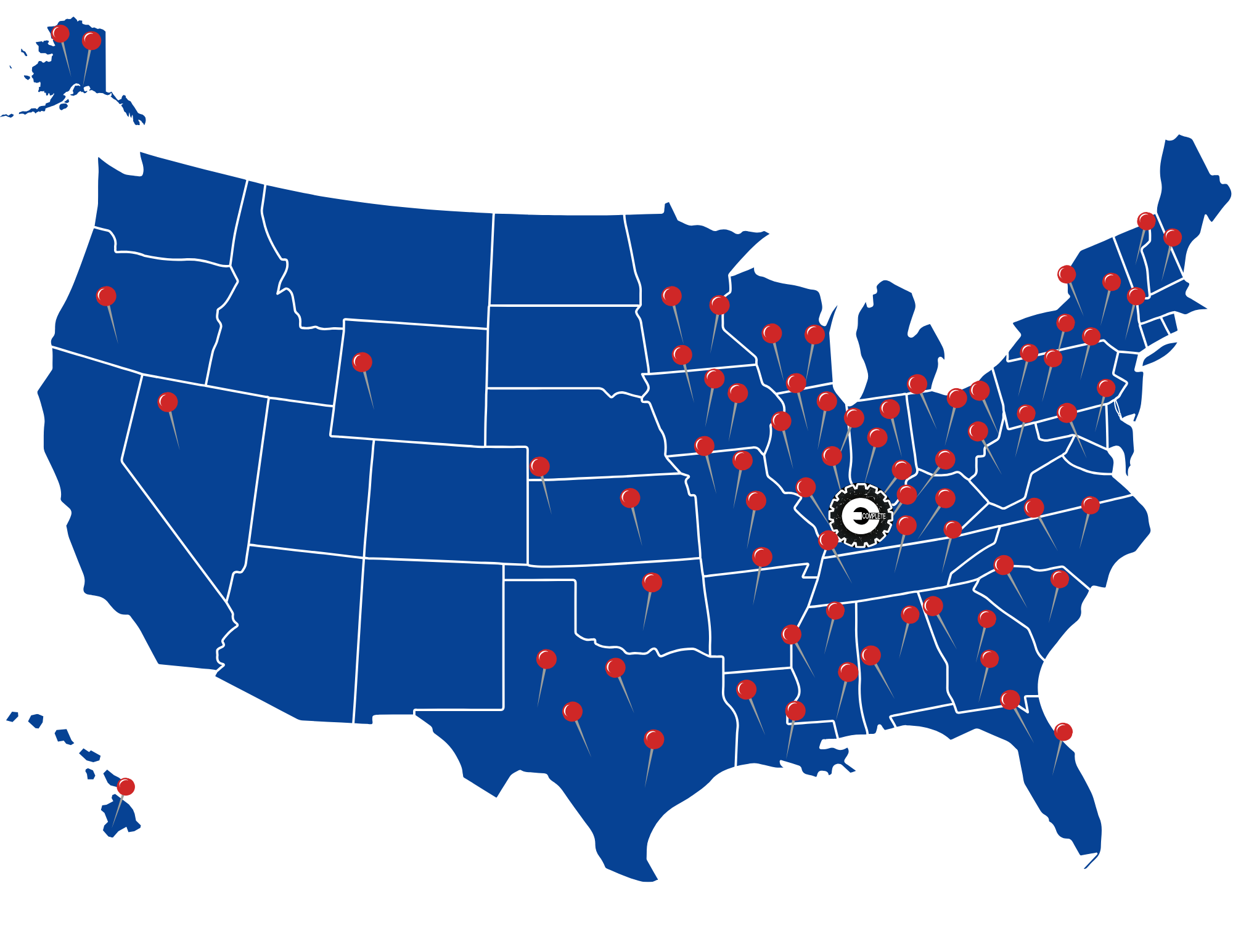

Serving facilities & municipalities

at home and nationwide

Recent Projects

Water Tank & Facility Services

painting & Specialty Coatings

Whether you need a brand-new coating or a renovation of an existing one, Complete Restoration specializes in delivering high-quality paint and coating services for tanks and facilities of all types.

From start to finish, our experienced team will guide you through every step of the process—ensuring a smooth, efficient, and professional experience.

Need a New Coating or a Renovation of an existing one?

Welding / Repair

Welding repairs needed for your storage tank or facility? We've got you covered.

Whether you're dealing with cracks, dents, corrosion, or leaks Complete Restoration delivers effective, lasting repairs tailored to your needs.

We offer cost-conscious solutions that never compromise on quality or safety. Whether it’s restoration or new installation, we’ll get your system performing at its best.

Got a Water Tank or Facility in need of Welding Repairs?

Water Tank & Silo Inspections

Monitoring your assets is no easy task — but we’re here to make it easier. Our inspection services are tailored to meet your specific needs.

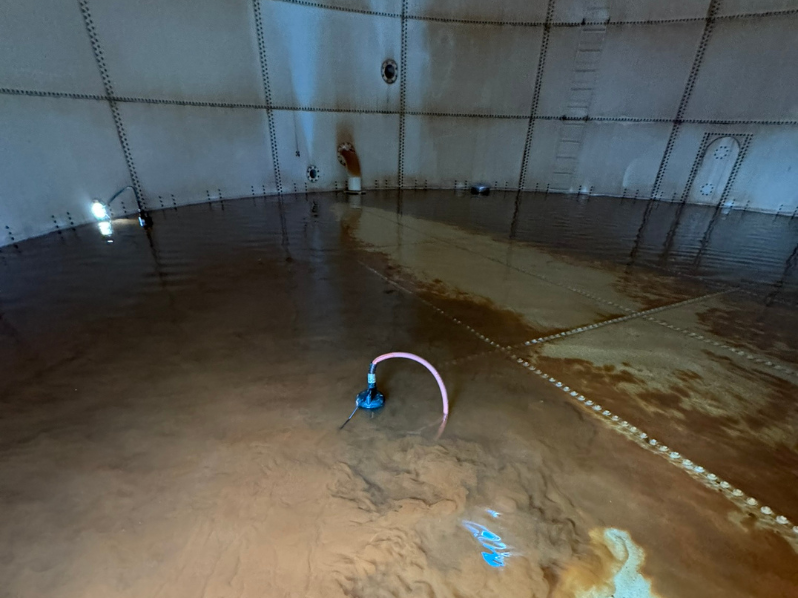

In-service inspections are conducted while the tank remains full and operational. Minimal preparation is required from you. Using Remotely Operated Vehicles (ROVs), we capture high-resolution video and photographs of the tank’s interior below the waterline. You can view the inspection live alongside our experts and ask questions in real time.

IN-SERVICE INSPECTIONS

Schedule Your In-Service Water Tank Inspections with Complete Restoration

Schedule Your In-Service, Flat Bottom Water Tank Cleaning with Complete Restoration

Out-of-Service Inspections

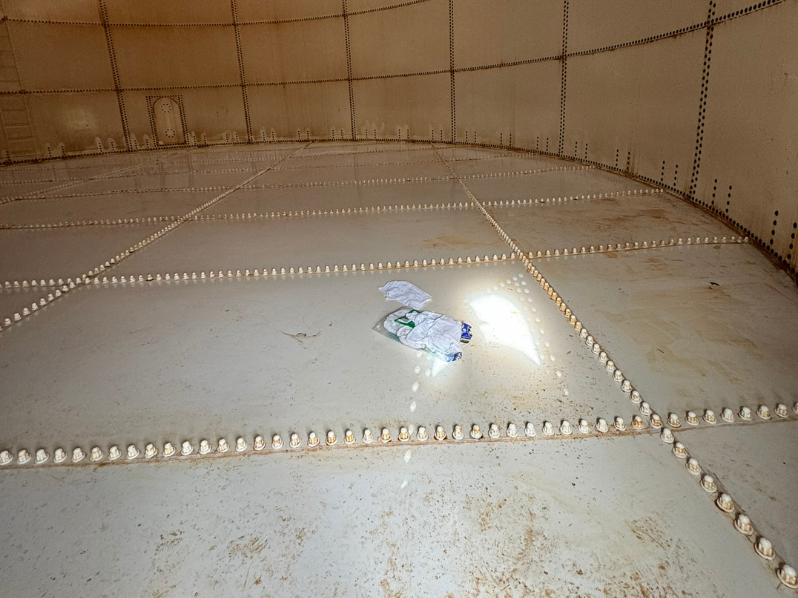

Out-of-service inspections are performed after the tank has been drained, purged, and ventilated. This method provides the most thorough assessment and is ideal when interior cleaning is necessary.

Did you know tanks used in fire protection systems, the NFPA mandates that the tank floor be cleaned of silt prior to inspection. They also outline required testing that must be completed. For potable water supply tanks, State and Federal regulations are carefully followed to ensure compliance. Inspections focus not only on the structural condition of the tank but also on identifying any potential risks of contamination.

Testing Services

Our testing services are offered on a case-by-case basis and are a valuable resource for clients seeking to identify hidden issues or make informed decisions for upcoming projects. Whether you're troubleshooting a problem or planning ahead, testing can provide critical insight during the decision-making process.

Below are some of the core testing services our team performs regularly. For tests that require analytical lab work, we can coordinate with one of our many trusted, nationally recognized laboratory partners to ensure accurate and reliable results

Core Testing Services

• UT (Ultrasonic Thickness): Ultrasonic Thickness Testing is a non-destructive testing (NDT) method used to measure the thickness of a material—usually metal—using high-frequency sound waves. A probe sends ultrasonic pulses into the material, and the time it takes for the echo to return is used to calculate thickness. It’s widely used to check for corrosion or erosion in pipes, tanks, and structural components without needing to cut or disassemble them.

• Mil (Dry Film Thickness): Dry Film Thickness (DFT) is the measurement of a coating’s thickness after it has dried or cured, typically measured in mils (1 mil = 0.001 inches). This test ensures that protective coatings (like paint or epoxy) are applied correctly, providing sufficient protection without being too thick or too thin. It can be measured with magnetic, eddy current, or ultrasonic gauges.

• Cross Hatch (Adhesion Testing): Cross Hatch Adhesion Testing assesses how well a coating adheres to a substrate. It involves cutting a grid (or "cross hatch") pattern through the coating, applying adhesive tape over the area, and then pulling it off to see how much coating detaches. The result helps determine the coating’s adhesion quality, often rated according to standards like ASTM D3359.

• Vacuum Box (leak detection): Vacuum Box Testing is a non-destructive method used to detect leaks or discontinuities (like cracks or pinholes) in welds or coatings, particularly on tanks, pressure vessels, and flat surfaces. A clear box with a vacuum seal is placed over a soapy liquid applied to the test surface. When the vacuum is drawn, bubbles will form at leak sites, making them easy to locate.

• Holiday Testing: Holiday Testing (also known as pinhole detection) is used to find flaws or discontinuities in non-conductive protective coatings applied to conductive substrates (like pipelines). A high-voltage or low-voltage probe is moved across the surface; if it encounters a defect (a "holiday"), the current completes a circuit and triggers an alert. This ensures complete coverage of corrosion-resistant coatings.